KC Hardware provides qualified lighting stamping parts for a wide variety of clients. We have a highly efficient process in short-run and medium-run periods. Whether you are making lighting fixtures for decoration or industrial use, KC Hardware has professional knowledge in metal stamping service, which can provide your enterprise with the highest quality Stamping metal parts. We will manufacture the components you need according to your exact specifications.

Our stamping metal for lighting parts is formed in " +/-.005" blanking size on the shear side of the part and +/-.010 forming size in the bend which has consecutive edges in fluent lines. The most advanced equipment and highly skilled staff enable us to provide stamped metal parts and sheet metal manufacturing that perfectly match your design. The metal materials we use are as thin as possible. Our lighting stamping also bears higher internal tolerances and external tolerances. What is more, we specialize in small to medium-sized lighting production and can maintain near-perfect repeatability of the stamping from the first part to the last.

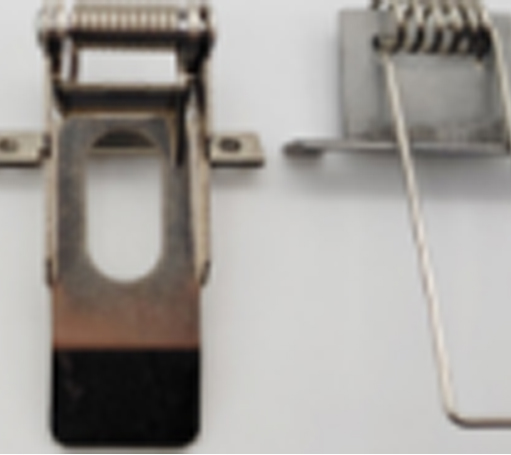

We can stamp all kinds of metals, including stainless steel, steel, aluminum, copper and brass. In addition, we have nearly 20 years of experience with various grades of aluminum, using the strength, lightweight, and corrosion resistance of aluminum assets to develop and manufacture thousands of industrial products. KC Hardware's aluminum, steel, and stainless steel lighting stamping have been used in indoor, outdoor, hazardous, water-based and extreme temperature lighting applied in not only industrial but also residential use.

Our team of metal stamping manufacturing experts uses top-level progressive die metal stamping technology and the most advanced quality control technology in stamping products. We also use high-end and mature technology in all stamping processes, from engineering to tool room, from production to inspection. We have also integrated online and offline camera vision systems and sensor technology to accurately capture product dimensions through camera images while the parts are running in production. This quality control technology allows us to track quality throughout the production process and ensure that the parts fully comply with our customers' specifications and tolerances.